The impact of exponential technologies is amplified further by collaboration—something Greater Peoria does quite well.

Additive manufacturing. Autonomy. Augmented reality. Exponential technologies are driving advancements across industries faster and more frequently than ever before. The impact of these technologies is amplified by collaboration, and we know Greater Peoria is a region that works together. It’s exciting to see cutting-edge advancements happening in our own backyard, like the recent collaboration between Caterpillar and OSF HealthCare to 3D-print exact replicas of hearts in preparation for patients’ surgeries.

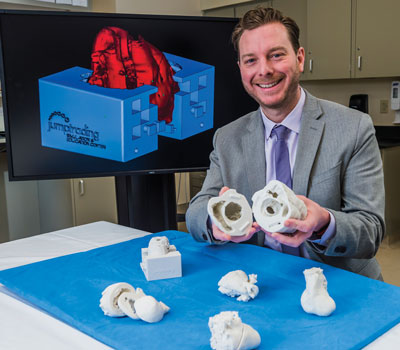

When I first heard this phenomenal story, I thought the idea of 3D-printing a heart seemed more like something that would’ve come in handy for the Tin Man in The Wizard of Oz than an actual reality. This part-to-heart story begins with Dr. Matthew Bramlet, Director of Advanced Imaging and Modeling for Jump Simulation (Jump), a collaboration between OSF HealthCare and the University of Illinois College of Medicine at Peoria. Dr. Bramlet, who is also a pediatric cardiologist at Children’s Hospital of Illinois, partners with engineers from Jump to segment and 3D-print babies’ and children’s hearts for surgical planning.

Seeing Hearts Anew

Seeing Hearts Anew

“In the past, we’ve been dealing with complex three-dimensional anatomy problems with two-dimensional technologies—that’s the benefit 3D printing has brought in,” explains Dr. Bramlet. One day, he had a conversation with a Caterpillar engineer who worked with 3D printing technology. That discussion and subsequent meetings led to a collaboration to create 3D-printed heart models.

While Jump has had the capability to print 3D heart models in-house for a number of years, the Caterpillar 3D printer offers a different way of “seeing” the heart with more advanced additive manufacturing capabilities. For example, the ability to 3D-print with a flexible material was the critical need in preparation for a patient’s surgery to be performed by Dr. Mark Plunkett, congenital cardiac surgeon at OSF HealthCare. “We had an older patient where we needed to excise heart muscle from the left ventricle in order to relieve obstruction,” Dr. Plunkett explains.

The team at OSF HealthCare agreed it would be a great benefit to have a 3D model of the patient’s heart made preoperatively of a more malleable material—something the surgeon could actually cut into so he could practice the surgery. “Think of it like batting practice before you ever step foot into the operating room,” notes Dr. Plunkett.

“We created a digital file of the patient’s heart, and the phenomenal engineers at Caterpillar 3D-printed it in a flexible material,” adds Dr. Bramlet. “By replicating the patient’s anatomy exactly… Dr. Plunkett was able to practice cutting the obstruction out prior to surgery. When he was in the actual surgery, he was able to make decisions based off a point of reference he otherwise would not have had. This is the purest form of simulation in healthcare.”

“The surgery went extremely well—quicker than it might have otherwise, since I had really already done the operation on the Caterpillar-made heart the night before,” says Dr. Plunkett. “I didn’t have to spend a lot of time in the operating room looking inside the heart and defining exactly where I was going to excise the heart muscle.”

“The surgery went extremely well—quicker than it might have otherwise, since I had really already done the operation on the Caterpillar-made heart the night before,” says Dr. Plunkett. “I didn’t have to spend a lot of time in the operating room looking inside the heart and defining exactly where I was going to excise the heart muscle.”

Driving the Mission

When the operation begins, the surgeon examines the inside of the heart and studies the structures prior to doing any surgical repair. During this time, the original surgical plan may be altered if there is an unforeseen structure or issue. To that end, 3D printing greatly benefits surgical planning.

Time is extremely valuable during the operation, as the patient is anesthetized and put on a heart-lung machine. They aim for operations to be as quick as possible, and shortened operating time often accelerates recovery.

“The innovation is amazing—something I wouldn’t have thought possible in my lifetime 10 years ago,” declares Dr. Plunkett, who has been practicing heart surgery for 20 years. “It’s moving forward rapidly and will have even more benefits in the near-future, from the clinical application of treating patients to the endless educational opportunities.

“Similar to Caterpillar, we have a mission-driven culture here which allows people to do what they think is best to serve that mission—even if it means doing something differently,” Dr. Bramlet adds. “The fertile ground for different thinking and creative problem-solving is driving the actions of our people, and that’s all ‘innovation’ is: creative problem-solving.”

Opportunities with Worldwide Implications

Opportunities with Worldwide Implications

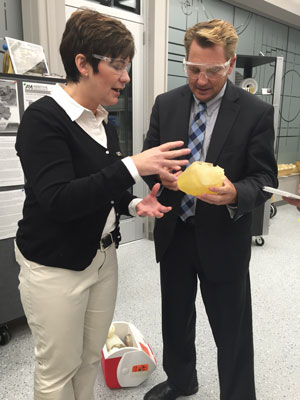

The opportunities in 3D printing and other exponential technologies—whether in healthcare, manufacturing or beyond—are endless. “For Caterpillar, working with OSF HealthCare provides us the opportunity to take advantage of complex geometries that our additive manufacturing engineers might not see on a day-to-day basis, allowing them to take what they learned and apply it to future applications,” says Stacey DelVecchio, Additive Manufacturing Product Manager at Caterpillar.

“To get the full capability of a 3D printer, you must have engineers who know how to use it,” adds Dr. Bramlet. “There’s no doubt in my mind the models we’re getting from Caterpillar are top-notch, because you don’t just have a printer: their engineers are top-notch, and you have quality. That’s remarkably demonstrated when we get a model back.”

“It’s exciting to have Caterpillar and OSF HealthCare joining forces,” says Dr. Plunkett. “With the depth of talent, resources and technology we both have, only great things can come—and I’m glad to be a part of it.”

Today, the hearts created by Caterpillar for Jump are for very rare and complex surgeries. Jump is one of only a handful of facilities in North America—and the only one in the Midwest—doing this high-level, detailed type of 3D printing work. In addition, they’re working to curate a 3D Heart Library for the National Institute of Health (NIH) 3D Print Exchange. This would allow other physicians access to 3D-print files of documented defects and could influence treatment plans of countless patients. With both Caterpillar and OSF HealthCare headquartered in Peoria, this homegrown collaboration may very well have worldwide implications. iBi

Henry Vicary is Guest & Community Relations Director at Caterpillar Inc.