Bradley University and Caterpillar Inc. team up with NASA to create revolutionary housing solutions for Earth and beyond.

“NASA is closer to sending American astronauts to Mars than at any point in our history,” proclaimed former NASA Administrator Charles Bolden on October 8, 2015, as the agency released a detailed plan outlining the next steps on humankind’s journey to the Red Planet. This journey, once rooted in the realm of science fiction, is well underway, and Peoria is at the center of those efforts.

With Caterpillar Inc. on board as a major sponsor, Bradley University is the official host of the NASA 3D Printed Habitat Centennial Challenge, a $2.5 million competition intended to advance the construction technologies needed to create habitats suitable for life in deep space. Later this month, the next stage of the competition will unfold right here in central Illinois—and the public is invited to witness the experience up close.

A Foundation for Innovation

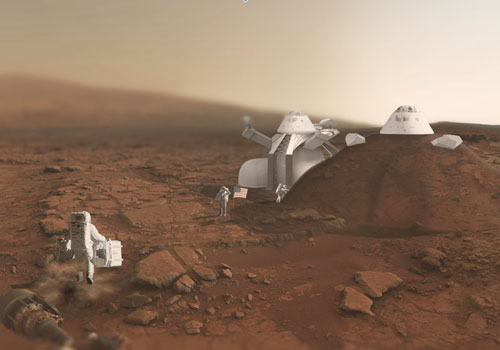

Any human journey to Mars will require a safe, reliable habitat to keep its crew healthy and productive for missions lasting up to three years. This structure must contain everything needed to comfortably sustain life—cooking areas, sleeping quarters and bathroom/hygiene facilities—and it must be adaptive to the planet’s hostile environment, where low temperatures and a thin atmosphere make it impossible for liquid water to exist on the surface, and no magnetic fields exist to shield humans from deadly solar radiation.

New, innovative technologies will be needed to transform Martian resources into water, fuel, air and building materials. “Space and weight aboard our vehicles are precious, and taken by the many other resources we will need for survival,” explains Steve Jurczyk, associate administrator for NASA’s Space Technology Mission Directorate. “That’s why we are seeking… to reuse the materials we will already be carrying, and combine them with what is already available at our destination.”

Together with its international and commercial partners, NASA is working to advance the science to bring this vision to life. Over the next decade, it will develop initial habitation capabilities for short-duration missions between the earth and moon, evolving these capabilities for lengthier missions in the latter part of the 2020s. By the 2030s, the agency expects the first human crew to set foot on Mars.

To lay the foundation for this historic feat, NASA began engaging the public in the process of developing the necessary technologies over a decade ago. Through NASA’s Centennial Challenges, cash prizes are offered to incentivize innovative solutions for problems of strategic national interest. By crowdsourcing this activity, citizens can get involved in research and development at the highest of levels, while new opportunities for business ventures can open up in the private sector. By expanding the range of problem solvers to encompass everyone from students to small businesses to independent citizen-inventors, the scope of possible solutions is also multiplied.

“They basically opened it up to the world,” explains Dr. Lex Akers, dean of the Caterpillar College of Engineering and Technology at Bradley University. “Hey, smart people in a garage… the next Apple corporation: give us your ideas! And they have come up with some fantastic responses from people who wouldn't normally be engaged in this sort of activity.”

Creative solutions for lunar landers, space elevators, fuel-efficient aircraft and astronaut gloves have already been generated through these Centennial Challenges. The 3D-Printed Habitat Challenge is sure to have a similar impact, with implications not only for Mars in the future, but on Earth today.

Team: GAMMA. Awarded: Second Place/People’s Choice Award, Phase One.A semi-autonomous, multi-robot regolith additive manufacturing system is used to create a protective shield around a modular inflatable habitat.

Deep Space Collaborative

Caterpillar’s relationship with NASA began more than a dozen years ago with joint research efforts in the areas of robotics and semi-autonomous/remote-operator systems. The company is also a sponsor of the NASA Robotic Mining Competition, in which teams design and build remote-controlled mining robots to navigate a simulated Martian terrain. Not only do such initiatives serve to inspire the next generation of engineers and scientists, they may also help the firm leap into a new emerging market: deep space.

Today, Caterpillar Inc. is a sponsor of the NASA 3D-Printed Habitat Challenge, along with Bechtel, the nation’s largest construction and civil engineering company, and Brick & Mortar Ventures, a San Francisco-based venture capital firm. “There’s no better way to solve big problems and come up with the next breakthrough than by working together with our customers, such as Bechtel, a true innovator in construction; a forward-thinking, sector-specific venture capital firm such as Brick & Mortar Ventures; our hometown university, Bradley, that is focused on innovation; and of course, NASA,” notes Eric Reiners, Caterpillar Automation & Site Technologies Program Manager. “Caterpillar and NASA have collaborated for years, and we are proud to work with NASA on this next great challenge.”

Bradley University got involved in the project through Dr. Akers, who observed the Robotic Mining Competition at the Kennedy Space Center in May. “I was contacted by Caterpillar, who heard about NASA wanting to do a Centennial Challenge on building habitats on Mars autonomously,” he explains. “So NASA brought a bunch of people down here, Cat brought some people, and we agreed to host a competition.”

A Three-Part Challenge

The 3D-Printed Habitat Challenge now underway is unfolding in three phases. Phase One, the Design Competition, was completed in 2015, prior to Bradley’s involvement. “The first phase was to brainstorm ideas for what a habitat might look like on Mars,” explains Dr. Akers. The submissions revealed a number of state-of-the-art architectural concepts, from habitats built through solar crafting, an innovative 3D-printing technique that would print structures using only sunlight and sand, to the Mars ICE HOUSE, a habitat created out of mined Martian ice—and the winner of Phase One.

“The second phase is the phase in which we're now involved,” he notes. “The goal is to 3D-print three basic structures.” Initiated in January, the Structural Member Competition moves from design concepts into the material technologies required to manufacture structural components for habitats, using some combination of recyclable materials and materials indigenous to Mars: namely soil, sand and rocks.

Teams from around the world may participate, except for citizens from countries on NASA’s Export Control Program list (Iran and North Korea, for example). International teams are also ineligible for the prize money. “Only U.S. teams can win the cash,” Dr. Akers explains. “But for a lot of people that's irrelevant.” Face time with the likes of Caterpillar and Bechtel, he adds, plus the teams’ retention of rights to any intellectual property they develop, offer far more valuable incentives. In the first of three sub-competitions within Phase Two, participants were tasked with 3D-printing two structural components of a potential habitat: a truncated cone and a cylinder. The second sub-competition involved 3D-printing a structural I-beam. At both levels, the teams were scored based on safety, the materials used and the maximum load of the components at failure.

The third and final level of Phase Two is the head-to-head competition that will take place at the Caterpillar Edwards Demonstration and Learning Center on August 23-27, 2017. After repeating the 3D-printing of cones, cylinders and I-beams on-site, each team must print a miniature dome capable of withstanding the loads and pressures found on Mars—and it must be done without human intervention.

“That's not easy to do,” notes Dr. Akers. “Many times when we build things, there are a lot of internal support structures, and when we’re done, we'd kick them all out. But this has to be completely autonomous: put the aggregate into the feeder, turn it on and stand back.”

The entire competition will culminate with Phase 3—the On-Site Habitat Competition—which will also be held at Caterpillar’s Edwards Demonstration Center in the fall of 2018. This final phase, which has a prize purse of $1.4 million, will focus on the actual fabrication of a scaled habitat—bringing the promise of 3D-printed habitats on Mars ever closer to fulfillment.

A Revolution in Housing

The journey to Mars is only the first step in NASA’s efforts to extend human presence deeper into the solar system. Along the way, human and robotic explorers alike are attempting to answer some of the most fundamental questions of the cosmos: Was Mars once home to microbial life, and is it today? Could it be a safe home for humans? What can it teach us about how life began on Earth? And finally, the ultimate mystery: Does life exist beyond Earth?

The revolutionary potential inherent in the 3D-Printed Habitat Challenge can be applied not only on Mars, but also on Earth. According to a 2014 report from the McKinsey Global Institute, 330 million households worldwide live in substandard housing or are financially stretched due to housing costs; an estimated $16 trillion would be needed to close this gap by 2025. In the meantime, the global housing crisis is projected to only get worse. A new approach to housing construction—a way to build homes quickly, efficiently, inexpensively and in a scalable way—would make these models irrelevant, significantly improving the lives of billions of people.

“Think about automatic 3D-printing of homes,” muses Dr. Akers. “After hurricanes, tornadoes, typhoons or tsunamis, you need fast, safe infrastructure. In 24 to 48 hours, you could build a habitat. Using indigenous material, you can go to places that don't have infrastructure, or are under real financial constraints, and build homes. War zones, for example—the military is quite interested in this capability.

“The current way we build structures could be the video rental stores of the future,” he adds. “And think about how big the construction business is… We’re interested in anything that's a disruption of a trillion-dollar business.” The additive manufacturing process also ensures that options for customization are practically limitless. “Today, if you want to build a home, we know it's going to be a fairly boxy, square sort of thing, and any deviation from that, the price goes up astronomically. That's not the case with 3D printing. Theoretically, if you feed it a different blueprint, it can make a structure as complex as you imagine. The printer doesn't care.”

With these new capabilities, the wildest dreams of architects and builders could become practical for the first time. “That's why Bradley's involved,” adds Dr. Akers. “We want to help educate students on a very disruptive and transformational way to build houses. And we have a big construction program and civil engineering program here. This could spin off in all kinds of areas.”

All Roads to Peoria

With two of the region’s key institutions partnering with the likes of NASA, the 3D-Printed Habitat Challenge brings prestige to Peoria, positioning it as a Midwestern technology hub. “Innovation thrives in the Peoria area,” declares Reiners. “This competition is a public example of what Caterpillar is doing every day with respect to innovation and technology development. Caterpillar is engineering the future of construction, mining and energy and transportation needs, right here in central Illinois.”

“Innovation, collaboration and experiential learning—three of Bradley University’s core values—are at the heart of the 3D-Printed Habitat Challenge,” adds Bradley University President Gary Roberts. “The challenge provides an unparalleled opportunity for students and faculty to network, create relationships with mentors, and explore new ideas as they partner in creating solutions for our world and beyond.”

Not only is this competition the ultimate real-world learning opportunity, it’s already attracted national attention to Bradley. “We've done webinars; we've been interviewed on television and radio. We were invited to a makers fair in the New York area to do a presentation on this project,” says Dr. Akers. “I gave a presentation at the Kennedy Space Center [in May]… This is all about promoting Bradley, Caterpillar and Peoria. It's a win-win.”

With the opening of its new business and engineering complex in 2019, Bradley will have the facilities and machinery capable of 3D-printing habitats in-house. And with Caterpillar's Global Research and Development Headquarters located here in central Illinois, “Peoria could be the world leader in the area of additive construction manufacturing,” declares Dr. Akers. “It could be a great business for Caterpillar, an intellectual business for us to put out students trained and exposed to these concepts. That's good for Peoria.” Not to mention: another giant leap for humankind. iBi

On August 26, 2017, the public is invited to the Caterpillar Edwards Demonstration and Learning Center to experience the NASA 3D Printed Habitat Centennial Challenge in person. Watch the teams as they print and test components that could one day be used to house astronauts on the Red Planet, and experience interactive displays from NASA, Caterpillar, Bradley and others. To reserve your spot, or for more information, visit cvent.com/d/x5q5mh.