How your company can manage its physical assets to extract their highest value…

Have you ever found yourself wondering when you should replace the roof so you get the most bang for your buck, while making it last as long as possible? Have you ever considered when might be the optimal time to address that old, deteriorated masonry wall? Perhaps you have asked yourself: When is the best time to apply a coating to your wood floor in the gymnasium? Moreover, how does one prioritize, plan, coordinate and budget any number of such projects?

Asset Management is an engineered approach that determines what facility assets you have, their condition, their performance and if they are doing what you need them to do at the best cost. It is a strategic approach that creates solutions to address shrinking budgets and rising demands on the built environment. More formally defined, Asset Management is the systematic and coordinated activity and practice through which an organization optimally manages its physical assets and their associated performance, risks and expenditures over their lifecycle for the purpose of achieving its organizational strategic plan. Because organizations have fewer dollars available to renew assets, they must become better at maintaining the assets they have, mitigating risks and extracting their highest value.

How It Works

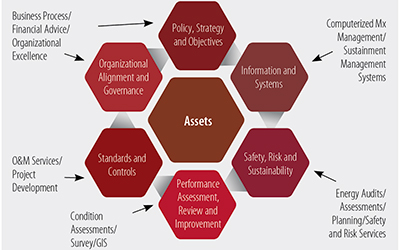

An Asset Management project is a multi-step process. A group of engineers and/or architects performs a comprehensive organizational needs assessment. This helps the professional team evaluate where a particular organization falls on a maturity scale by looking at its policies, practices and capabilities, while identifying gaps and shortfalls in the overall Asset Management strategy. The figure below summarizes the maturity categories.

The next step is to conduct on-site condition evaluations while considering and maintaining goals set forth in master planning strategies. This helps each organization create an inventory of its assets. Each evaluated area is then rated, and a roadmap is developed that charts specific actions. Roadmap recommendations may include: training for the O&M (operations and management) workforce; facility commissioning and/or retro-commissioning to create maintenance strategies for new and existing facilities; building system monitoring for real-time performance feedback; and/or implementation of a Computerized Maintenance Management System (CMMS) and Sustainment Management System (SMS). [Note: A CMMS records, manages and communicates the day-to-day operations, while an SMS is a decision support tool to forecast the aging of systems to determine best scenarios for investments to prolong remaining service life.] The full breadth of the Asset Management framework is illustrated below:

A Guiding Concept

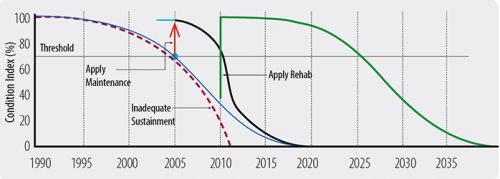

Asset Management is a powerful approach to evaluating component degradation while balancing financial inputs for asset maintenance or replacement. It ensures the longest service life and brings the highest value to the organization. Every element and aspect of the built environment experiences degradation over time, so it is vital for organizations to know when to apply maintenance to components and when to replace them, in order to reduce the impact of degradation to the overall condition of the built environment and the organization itself.

To illustrate this point, refer to the following graph. After a component is installed, its degradation is slow at first, but accelerates as time progresses. The organization can apply maintenance to the component, but that will only extend its lifespan for a finite amount of time before total rehabilitation or replacement is needed. Asset Management helps map out the best scenario(s) for the most beneficial time(s) to apply maintenance or rehab that align with the organization’s financial capacities and budget capabilities.

Referring again to the figure above: when a roof is installed, it will show little aging for the first 10 to 15 years, as illustrated by the blue line. After that point, its performance will begin to degrade more rapidly (the dashed red line). If a coating or other maintenance strategy is applied to the roof at 15 years from the date of original installation (blue dot), it could extend the life of the roof for another five to 10 years before rehabilitation is needed, as demonstrated by the blue-gray line. The green line demonstrates a complete replacement of the roof after 20 years. This model, of course, impacts plans and budgets, creating opportunities to contend with and balance against other degrading components through the built environment. iBi

To learn how Asset Management can help you optimize financial inputs, call Scott Burge at (217) 352-4169 or email him at [email protected].